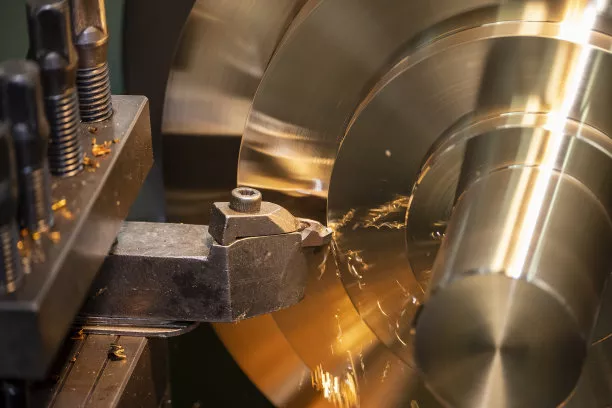

Do you have a passion for machining brass? If so, you’ll love this ultimate guide for brass CNC machining! In it, we’ll teach you everything you need to know about this fascinating process, from the basics of metalworking to more advanced techniques. Whether you’re a beginner or an expert, we have the information you need to get started with brass CNC machining.

Introduction

The Brass CNC Machining process is a versatile and precise way to create custom parts. It can be used for a variety of different tasks, from small adjustments to large manufacturing runs.

This guide will teach you the basics of brass CNC machining, from setting up your machine and selecting the right materials to using special techniques for making highly accurate parts. We’ll also cover common problems and solutions, so you can get started on your next project quickly and with confidence.

CNC Machine Basics

A CNC machine is a computer-controlled machine that can produce finely detailed parts with very little human input. That means you can easily create things like jewelry, furniture, and even cars—all without having to hand-shape them by hand.

There are a few things you need in order to get started with CNC machining. The first is a computer with a suitable operating system and printer interface. You’ll also need access to software that allows you to design and produce your parts using CAD ( Computer Aided Design) or CAM (Computer Assisted Machining) software. Once you’ve got all of those things set up, it’s time to learn how to use them!

What is CNC?

CNC stands for computer numerical control, and it is a process that uses computers to control the speed, precision, and position of a milling or cutting tool. This technology allows you to create intricate parts with amazing accuracy and speed.

There are many different types of CNC machines, but all of them rely on two basic principles: motors and rotary tables. Motors move the tool while the rotary table follows the path you specify. By using these two technologies together, you can create almost any shape or design you can imagine.

Some popular applications for CNC include: car manufacturing, engineering components, medical equipment, furniture fabrication, and more. With so many possibilities for what you can create with CNC technology, there’s no limit to what you can achieve!

The Difference Between Bush, Milling, and Drilling Mills

There are many different types of mills, each with its own specific benefits and drawbacks. Here’s a look at the three main types: Bush, Milling, and Drilling Mills.

Bush Mills are the oldest type of milling machine, dating back to the 16th century. They’re simple machines that use a round or cylindrical grinder to grind materials like wood or metal. Because they’re so basic, Bush Mills are limited in their capabilities. They can’t handle high volumes or complex shapes, and they don’t produce very precise parts.

Milling Machines were developed in the 18th century as a response to the limitations of Bush Mills. Milling Machines use horizontal rotors called spindles to grind materials into fine particles. This increased precision and volume capacity over Bush Mills, making them popular for manufacturing intricate parts like gears and bearings.

Drilling Machines became popular in the 20th century as they increased accuracy even further than Milling Machines. Drilling Machines use rotors with multiple axes to create holes in various shapes through soft materials like plastic or metal. This eliminates the need for hand-held tools and makes for much smoother parts with less distortion.

Benefits of CNC Machining

CNC machining is a precise and efficient way to produce parts. Benefits of using CNC machining include:

1. Precisely produced parts – with CNC machining, you can create parts that are extremely accurate and consistent in size. This results in less waste, decreased manufacturing time, and overall improved quality control.

2. Reduced manufacturing time – due to the accuracy of CNC machining, it can be faster than traditional methods such as stamping or forging. This means quicker turnaround times for products, which is beneficial for businesses that require high-quality products quickly.

3. Increased production efficiency – because CNC machines are so precise, they can be used to produce multiple pieces at once with minimal wasted material. As a result, your machine will be more productive and able to handle larger orders more quickly than traditional methods.

How to Start in the Industry

If you are interested in starting in the brass CNC machining industry, there are a few things you need to do first. First, find a company that is already doing this type of machining. Many companies use subcontractors to do their machining, so it is important to be aware of which companies are involved in the process and who your potential subcontractors are. Next, research the types of machining that the company does. After you know what type of work is being done, start to learn more about the process and how it works. Finally, get started by practicing on simple parts until you feel comfortable with the machine and the process.

Tips to Stay Safe in the Industry

There are a few things you can do to stay safe in the brass CNC machining industry. First and foremost, always use safety glasses when working with brass. They will protect your eyes from debris and scratches. Additionally, wear a dust mask and gloves when milling brass because the dust can be very harmful if inhaled. Finally, make sure to keep an eye on your work area at all times and be aware of potential hazards nearby. Read More https://yijinsolution.com/