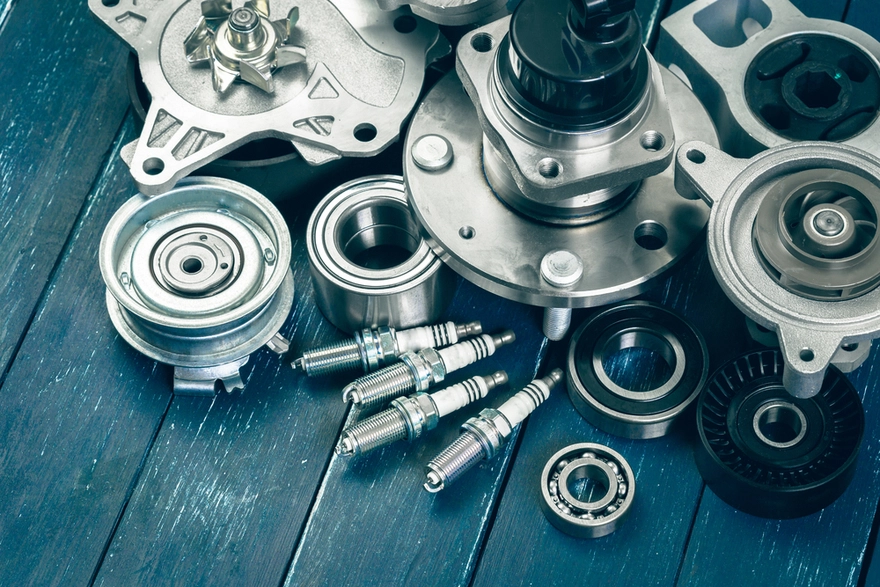

The industrial process of returning a used, worn-out, or inoperable product or auto part to its previous state with improved performance is known as remanufacturing. The core transfer case of a remanufactured part is completely disassembled, checked for issues, and then put back together using both new and used auto parts. The finished product is almost identical to brand-new auto parts.

The closest car parts to new ones are those that are remanufactured. The manufacturer replaces the components that have seen the most wear with the new ones.

Hand-selected transfer case cores of the highest caliber are employed in subsequent remanufacturing. They undergo a rigorous assessment before the remanufacturing process.

Depending on the make and model of the vehicle, the cost of remanufacturing differs. A remanufactured transfer case might cost about the same as a new one. When compared to brand-new products, remanufactured goods can also boost your profit margin by enabling you to

Cost-effective

Remanufacturing could help your business save money. Consider the price of energy, water, raw materials, and the product’s life cycle on the environment. Reduce the amount of rubbish you need to have disposed of to save money.

Increase Your Employment Opportunities

Although new parts are frequently created outside of the United Kingdom, local remanufacturing is more cost-effective. Remanufacturing promotes the evolution of specialized expertise and the creation of jobs in the local economy.

Remanufacturing in the UK can also reduce new part waiting times, increase product availability, and reduce transportation costs, time, and environmental effects.

Improve Performance

It is advantageous to promote new products and services. Use current manufacturing processes. It requires training new employees, investing in the staff, and enhancing material traceability.

Services with Added Value Encourage Goodwill

Despite the greater labor and equipment costs, remanufactured components cost more than refurbished parts but are of higher quality and have a longer lifespan. Remanufactured components are more durable and of higher quality.

Remanufactured parts are also significantly less expensive than new parts because they are constructed from recycled resources. Savings in raw material and energy consumption result in a finished product that is 40 to 50 percent less expensive than a new one. It provides a greater margin in a market where prices are extremely volatile.

More information

Collect useful data to enhance the product’s functioning and design. It makes it possible to enhance post-sale operations.

Contribute to environmental preservation

Manufacturers and drivers seeking environmentally friendly substitutes commonly utilize remanufacturing. Around 85% of an engine’s original components are kept.

Many metals, including steel, aluminum, and other unsalvageable materials, are recycled regularly in a variety of ways to reduce the quantity of waste thrown in landfills. Remanufacturing cuts CO2 emissions significantly since it uses between 80 and 85 percent less energy than creating new parts.

Conclusion

Manufacturing is profitable for companies that care about doing the right thing. In many new cars, a brand-new transfer case is typically produced. When transfer parts are no longer functional, manufacturers just sell new parts to make a profit. They continue to use previously manufactured cases while rebuilding and modifying them. The transfer part’s quality is ensured during the remanufacturing process.