Plastic material is used for a variety of purposes today across different industries. Different sized components are used for different commercial and industrial purposes. Not a lot of people know how these plastic components are made, though. Injection molding is a fairly common process that helps in manufacturing plastic components for different applications. This article will try to outline what plastic injection molding is. We will also discuss the role of a plastic molding company and how they go about the entire process.

What Is Injection Molding?

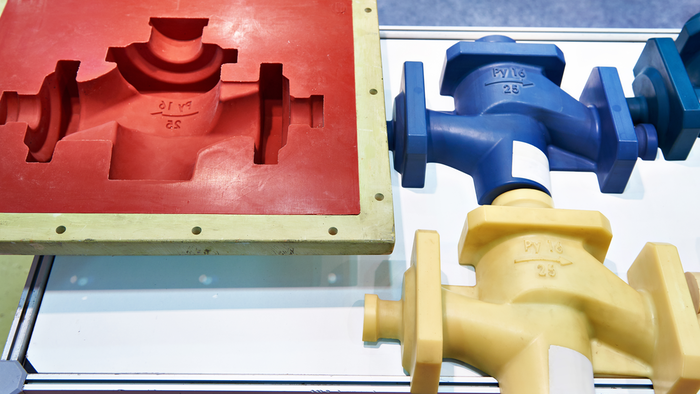

Injection molding is a process that uses heat to melt and mold plastics into the desired shape through metal molds. The molding machine can be hydraulic or electric, depending on the facilities of the plastic molding company and the final application of the plastic component.

If we specifically talk about plastic injection molding, it is predicted to see a compound annual growth rate of 4.6% by the end of 2028. Plastics are of different kinds and are used based on the final use and the industry for which it is being manufactured. Here are some reasons why plastic is used for injection molding:

- The process offers high flexibility to the clients in choosing the type of thermoplastic. Medical-grade plastic will be different from those used in chemical industries.

- High precision components can be easily manufactured with plastic because mold design is easy to execute. Complex parts can be made with precision with the right equipment.

- Thousands of components can be produced per hour, depending on the efficiency of the machines. Electric machines are preferred for mass production in a time crunch.

- The tolerance of the machines is tight enough to provide consistent performance in all of the products being manufactured. The thermoplastic will be used to create multiple components with the same features of consistent quality.

- Any plastic molding company will tell you that the creation of components is relatively cheaper after the initial mold design. Mass production is made easy once the mold is finalized.

How Does Plastic Injection Molding Work?

The plastic injection molding process works in multiple steps, which we will briefly mention here.

Step 1: Choosing the right thermoplastic.

Step 2: Finalize the mold design and the material for the construction of the mold.

Step 3: Melting and injecting the thermoplastic into the mold.

Step 4: Holding the components and allowing them to cool uniformly.

Step 5: Ejection and supplying the components.

The Takeaway

Any plastic molding company will assist you in understanding certain details of the process which impact the durability of the components. Thermoplastics have different varieties, and all of them have different properties which can be applied to different industries. It is essential to know the complexity of the mold before finalizing the type of plastic. One has to accordingly manage the compatibility of the thermoplastic with the tolerance required from the part. After the mold is manufactured, mass manufacturing through injection molding is made easier.